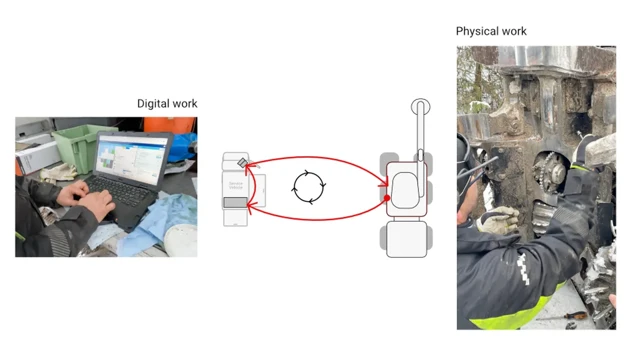

Mechanics work in two modes, a digital and physical world, and have to switch between them constantly.

MaxiFlare

MaxiFlare improves mechanics' performances by enhancing their tools. Through field research, our team found a disconnect between the mechanics' physical work and their digital responsibilities, related to reporting and learning. To mend this gap, we infused one of their trusty tools, the flashlight, with digital capabilities, allowing mechanics to do their reporting and learning easily while out in the field. A projected interface, controlled with a physical button, allows them to access their reporting software and digital manuals. Video and audio recording features allow richer and easier reporting, further merging the digital and physical world.

The Course

The overall aim of the course is to provide practical experience of designing a complex product or system with a focus on specialized use, through three modules: Foundations, Project and Sensemaking.

The course is carried out in collaboration with Komatsu Ltd and Komatsu Forest.

Ece Günesen

Xingyu Liu

Tianlong Mu

Tom van Wijland

In collaboration with:

MaxiFlare Project Video

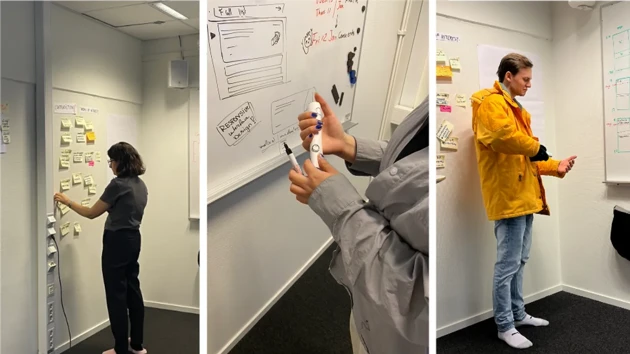

The team examined field research and developed ideas through on-the-wall analysis, lo-fi prototyping and role play.

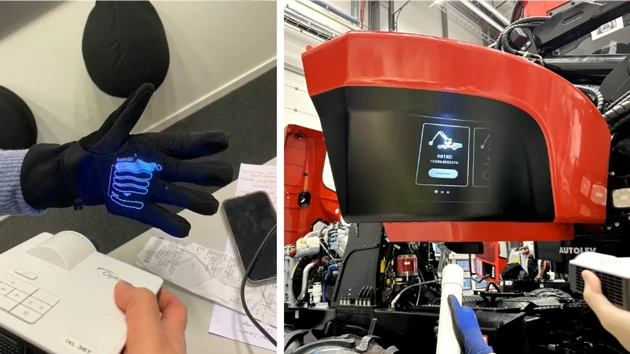

The feasibility of the projected interface was tested extensively at several stages in the project.

The Komatsu MaxiFlare is controlled with a single multifunctional button. The top part can be twisted to access the 3 operation modes.

A mechanic uses the MaxiFlare to project the reporting interface on the machine.

The mechanic chooses whether a certain part of the machine they just examined has to be repaired immediately, or if a repair is scheduled later.