CUDA: Advanced headlight system, equipped for all underground miners.

CUDA

Although 5G network technology and gas outburst disaster prediction in underground mines is developing, inefficient communication and non-adaptive blind evacuation navigation still pose significant safety risks. This project aims to distribute advanced technology to underground workers in a smart, cost-efficient manner, enhancing the transparency and timeliness of disaster information as well as the accuracy and real-time availability of evacuation navigation. Working closely with stakeholders, the design process included on-site user research in underground mines and interviews with industry workers and researchers, followed by iterative prototyping and on-site validation. The final design of the CUDA system features an advanced headlight and intelligent gas detector, seamlessly connected to the ground information center via the underground 5G network. Data from sensors and cameras are analyzed by an AI-assisted system, notifying miners of disasters in real time through visual alarms in the headlight system. The information center analyzes tunnel conditions, shelter capacity, and optimal evacuation routes, providing real-time guidance via the headlight's navigation module. Safety inspectors use intelligent gas detectors with uncooled Optical Gas Imaging cameras to quickly locate gas leaks, sharing real-time data with the information center to prompt ventilation team responses.

Project information

Although the development mining industry has been slowing down in recent years, it still plays an important role in the economies of a number of countries, while the global base of underground miners is still large. As underground mines continue to be developed, the depth and complexity gradually increase, and so do the risks of all kinds of mine disasters. However, inefficient and unintuitive disaster communication and non-adaptive blind evacuation navigation are wasting valuable response time and putting the lives of underground miners at risk. The aim of this project is to reflect on and upgrade the existing personal equipment of underground miners in order to better align and fit with the development of underground 5g networks and gas outburst prediction technologies in the next 3-5 years, which will enhance the transparency and timeliness of underground disaster information, as well as the accuracy and real-time navigation of evacuation in the emergencies. It also reflects the impact that being an industrial designer can have in such an extreme and specialised field and environment, by placing a greater emphasis on the interests and safety of each individual miner's life and consideration for the countless families behind them in the broader context of the pursuit of capacity efficiencies and economic benefits.

Methods

In the early stages of the project, I did a lot of desktop research, not only to understand the whole workflow of mining but also to gain a deep understanding of the social group of miners and the social phenomenon behind it. Afterwards, I returned to Southwest China and conducted two days of fieldwork in an underground mine and at the Gas Outburst Forecasting Research Centre. I observed the working environment of different stakeholders: mechanical mining team, ventilation team, digging team, drilling team and safety inspector, and conducted online interviews with various miners and researchers with different experiences. These helped me to gain insights into the underlying meanings of some of the user behaviours and their intended purposes. Research on trends in underground mines also has been done and I found out that underground 5g network construction is gradually starting to develop and be applied, and the mine I did field research is also planning to start underground 5g planning and construction in 2025. After this, I explored multiple design concepts. While conducting immersive ideation workshops and experiential prototype test-outs with classmates, I also stayed in close contact with multiple miners and got their feedback based on their work habits and experiences. One of my design goals was to minimise their learning curve by fitting as closely as possible into their existing familiar user processes. At a later stage in the project's development, I optimised various design details through rapid model iterations to ensure that they were ergonomically suited to underground mine environments and that they were failure-proof in extreme, emergency and low visibility situations. I then took the models back to the mines in China for on-site model review with local miners, where my designs were much appreciated by them.

Result

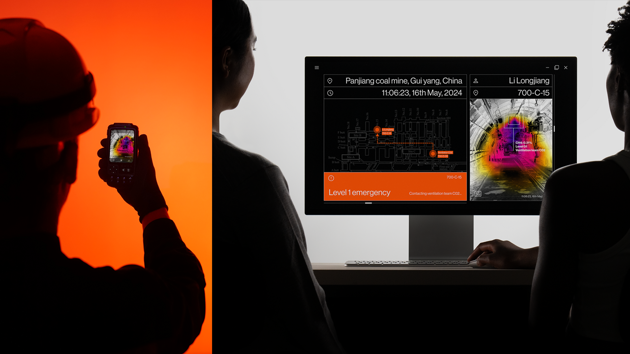

The final design of the CUDA system features an advanced headlight and intelligent gas detector. Both are seamlessly connected to the ground information center via the underground 5G network, where data from the underground monitoring sensors (crustal stress / gas level / airflow speed) and cameras (roof collapse / underground fire / underground flood) are gathered and analyzed by an AI-assisted system. During emergencies, miners are notified of disasters level information in real time through visual alarms in the headlight system. If evacuation is required, the information center will analyze tunnel conditions, emergency shelter capacity, and optimal evacuation routes, providing real-time navigation to miners via the headlight's navigation module. So miners can be evenly distributed to the nearest emergency shelter, and travel safely and quickly to the assigned location. For safety inspectors, they will be equipped with intelligent gas detectors with uncooled Optical Gas Imaging cameras, which allow them to quickly and accurately locate gas leaking sources, and to share real-time images with the information center. The products have been designed with long working hours in an environment such as an underground mine in mind. Both the headlight system and the gas detector are guaranteed to operate at full power for 16 hours, which equals two working days for a miner. Many details have been taken into account to protect against dust, water and impacts, and to ensure that it can be operated in low visibility, and stressful emergencies. For example, the glove-friendly touchscreen is combined with large physical buttons to handle all situations; all buttons can glow in the dark to ensure operability; and the hook structure on the front and back of the headlight ensures stability in emergencies and compatibility with a wide range of existing safety helmets.

In collaboration with:

CUDA: Intelligent gas detector, equipped for safety inspectors.

Multiple lighting modes respond to different situations and provide timely disaster notification.

Navigation led module connected to the infor center via 5G, provides real-time evacuation guidance.

Optical gas imaging camera helps locate gas leaking sources, and buttons glow in the dark to enable operability.

Clear and intuitive user interface enables readability and easy understanding in low-visibility environments under emergencies.

The safety inspector transmits images of gas leaking source located by gas detector to the information center in real time.

The design details are all made for long-lasting in the extreme environments of underground mines.

Field research at the depth of 800 meters underground.

Rapid model iteration, experience test-out, and on-site concept validation with stakeholders.