About the thesis defence

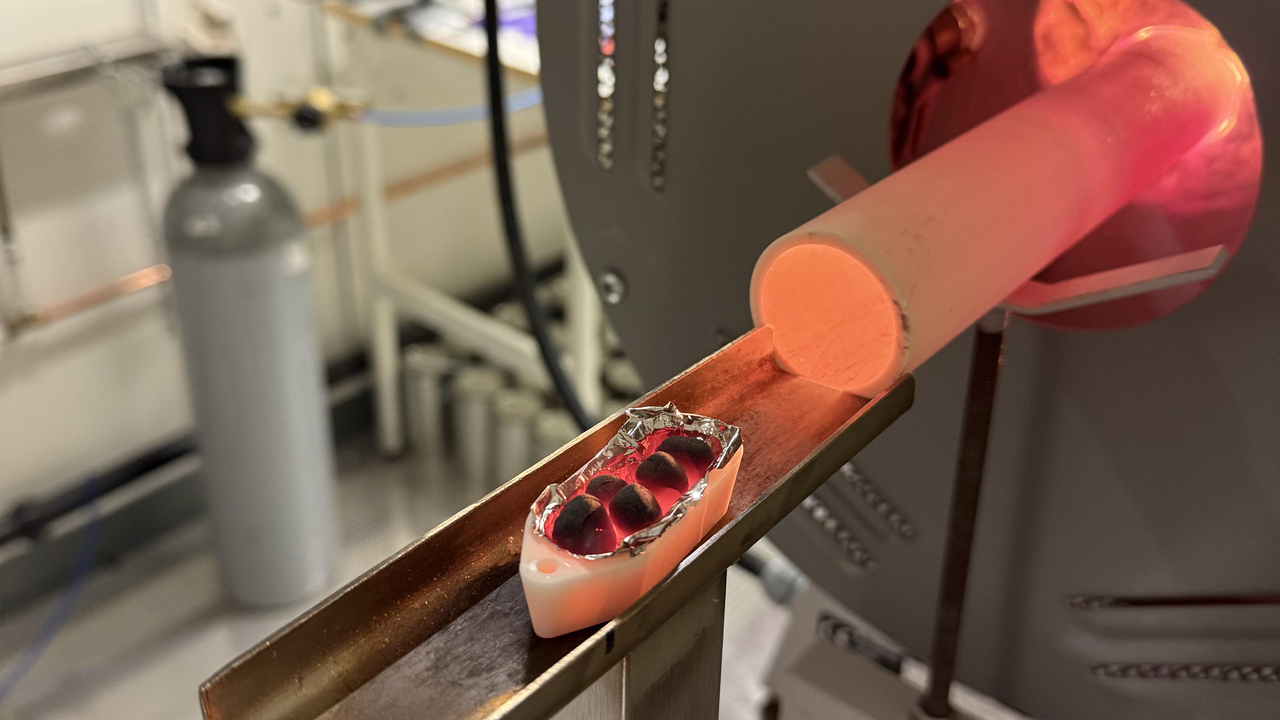

On Thursday, 20 March, José Aguirre Castillo, Department of Applied Physics and Electronics, will defend his doctoral thesis titled “Cement clinker formation in concentrated carbon dioxide atmospheres. Mineralogical and reactivity insights”. The defense will take place at 13.00 in KBE301 – Lilla hörsalen in the KBC building.